Pioneering Excellence in Laser Automation Technologies

At LSS Automation Company, we specialize in cutting-edge laser automation solutions designed to revolutionize manufacturing, production, and industrial processes. Combining advanced laser technology with intelligent automation, we deliver unparalleled precision, speed, and efficiency tailored to meet the evolving demands of modern industry.

From laser cutting and welding to marking, engraving, and custom automation systems, our solutions are built for performance, reliability, and scalability. Trusted across sectors such as automotive, aerospace, electronics, medical devices, and more, we empower our clients to achieve higher productivity and superior quality.

Driven by innovation and backed by a team of industry experts, LSS Automation Company is not just a technology provider—we're your partner in progress.

MOST POPULAR

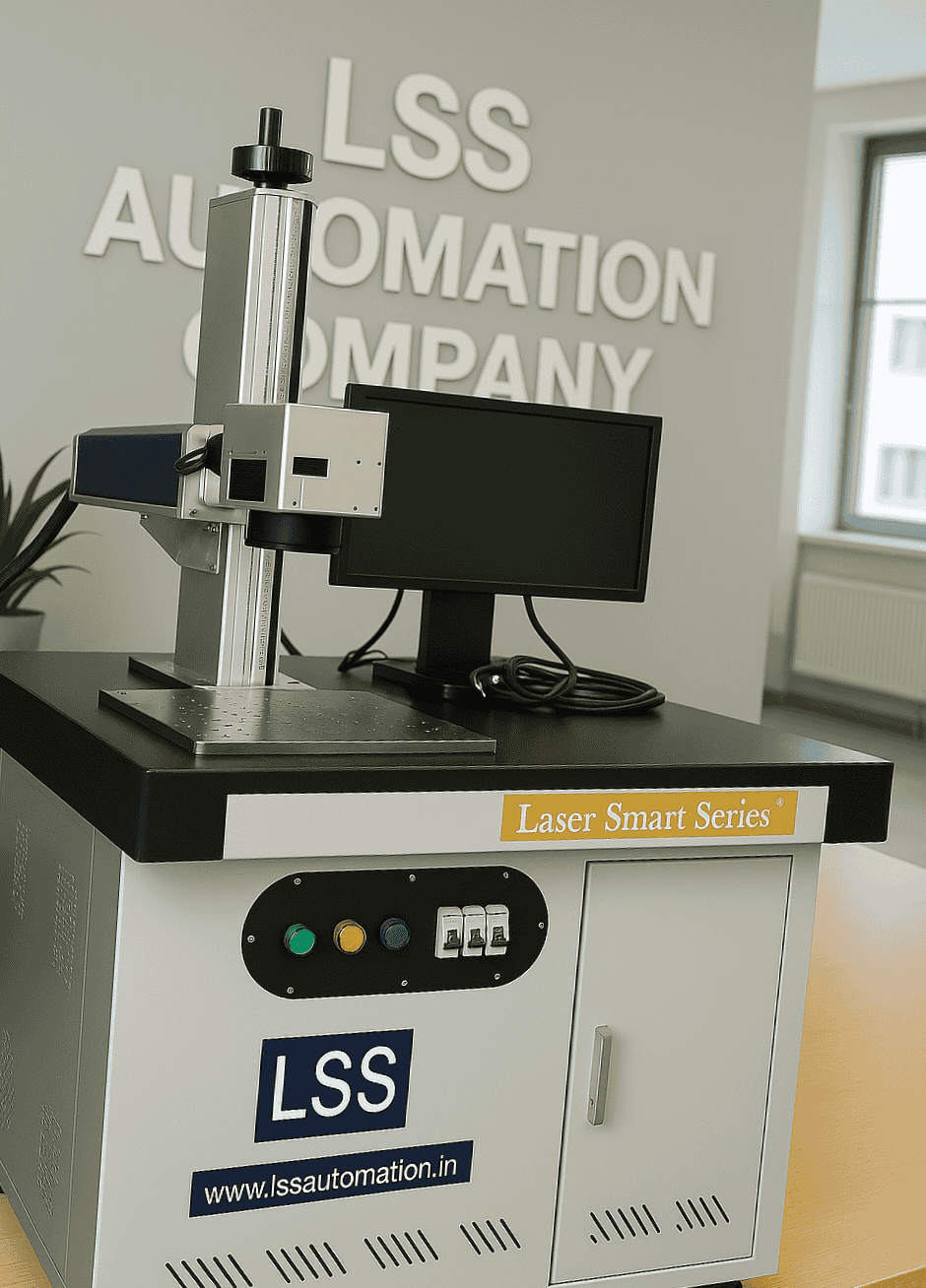

LSS Automation Company is Laser Marking Machine Manufacturer in India, Metal Laser Marking Machine Manufacturer in India, Fiber Laser Marking Machine Manufacturer in India, Led Laser Marking Machine Manufacturer in India, Laser Machine Manufacturer in India, Laser Manufacturer in India. LSS Automation Company Offers Sales and Service of Laser Cutting Machine in India, Fiber Laser Cutting Machine in India, Metal Laser Cutting Machine in India. LSS Automation Company is focused to provide the solutions related to marking and engraving on components. We provide the best solutions to the clients related to their marking needs to trace, identification, and best quality of marking in less time with the most affordable prices.

LSS Industrial Laser Source

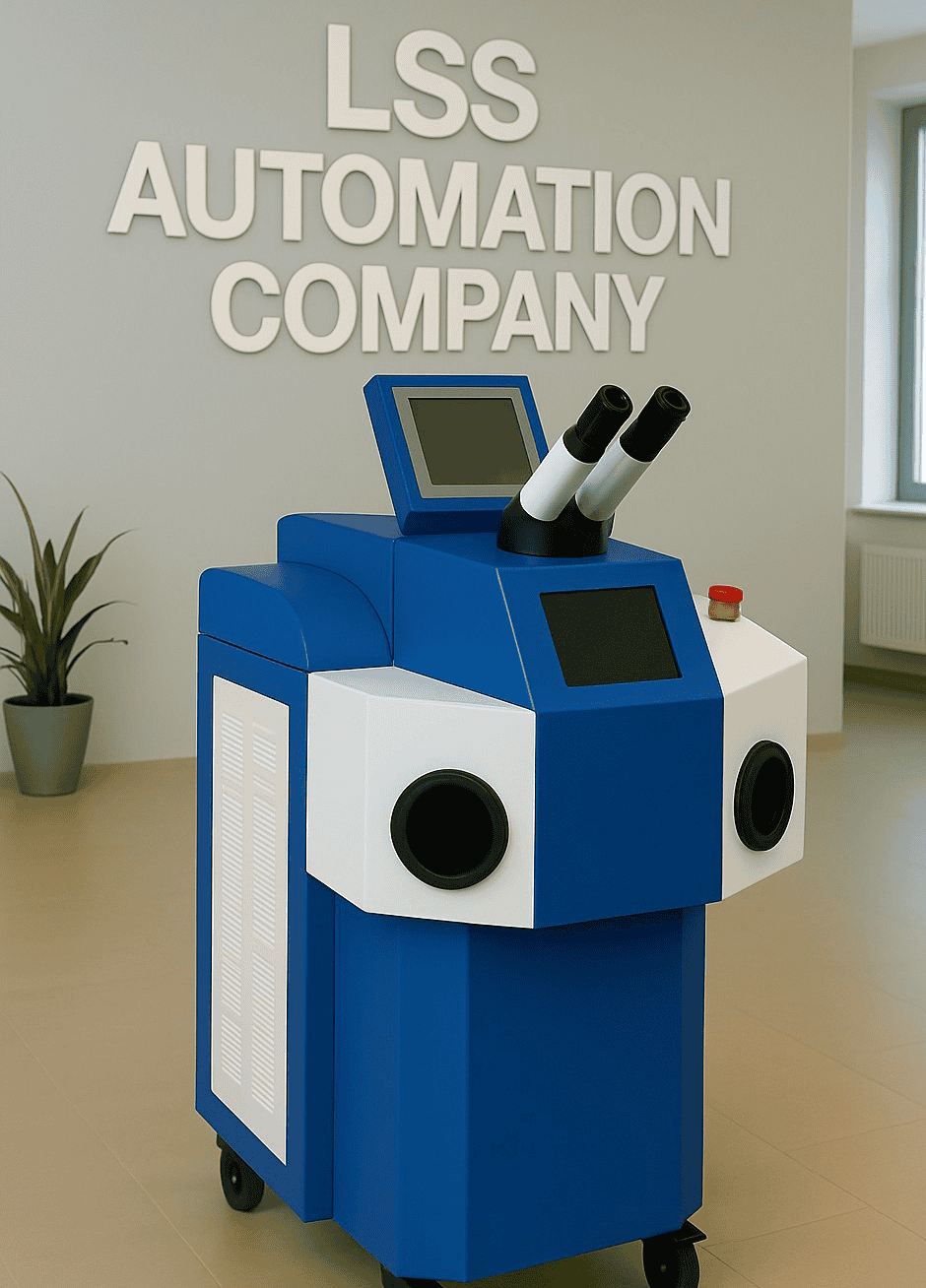

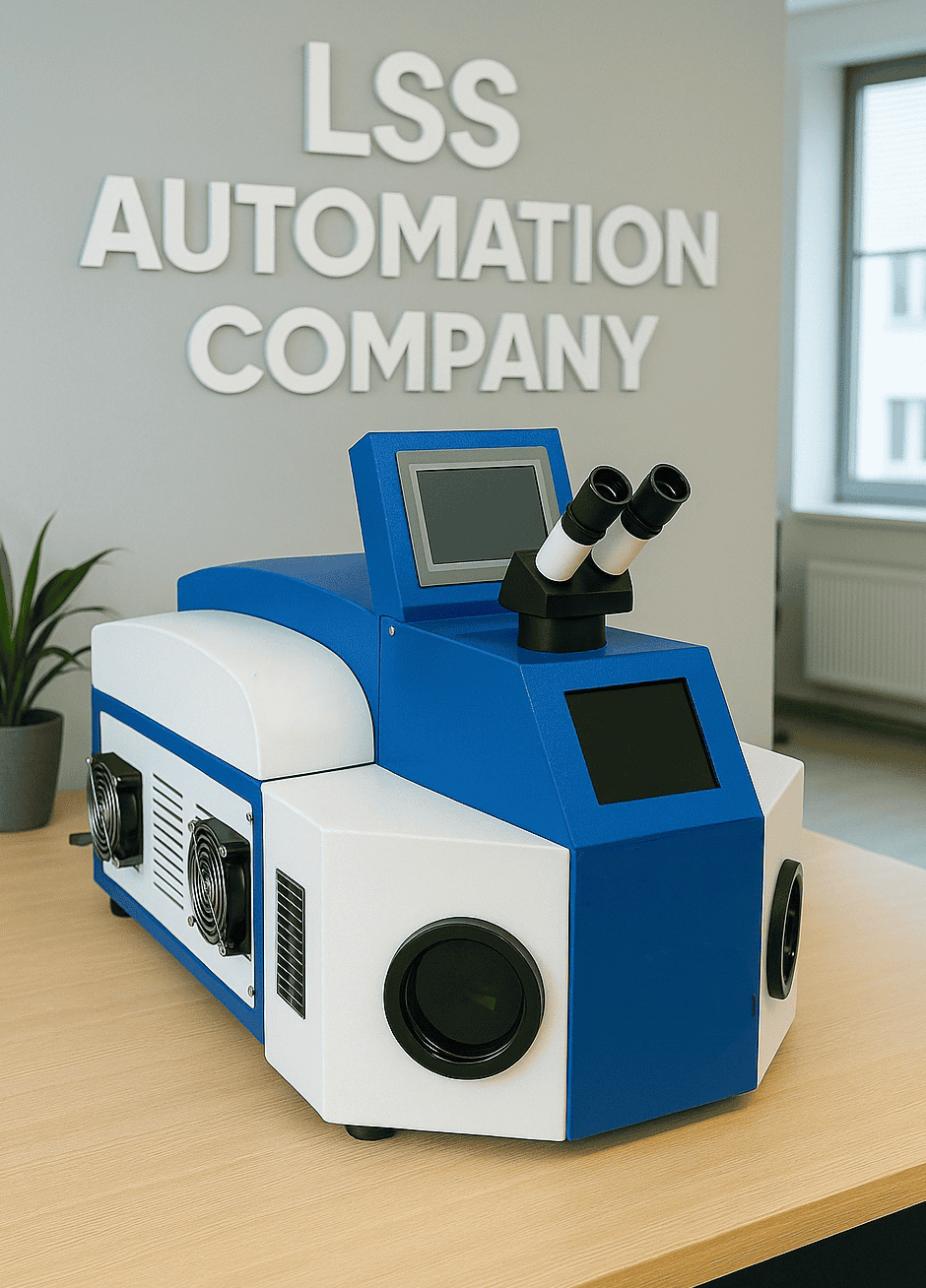

Our company's scientist holds a patent in the laser industry, reflecting our commitment to innovation. Japanese and German companies use our machines, demonstrating their advanced technology and reliability. We provide solutions for marking, cutting, and other applications, using high-quality parts to ensure long-lasting performance in extreme conditions.

Why Choose Us

Industry-Leading Expertise

With years of experience in laser technology and industrial automation, our team brings deep technical knowledge and a proven track record of successful implementations across a wide range of sectors.

Customized Solutions

We understand that every application is unique. Our systems are designed to meet your specific requirements — whether it’s high-speed precision cutting, micro-welding, or integrated production line automation.

Cutting-Edge Technology

We leverage the latest advancements in laser and automation technology to deliver solutions that are fast, accurate, and built for the future.

Quality & Reliability

Our commitment to quality ensures that every system we deliver meets the highest standards for durability, performance, and consistency — even in the most demanding environments.

Global Reach

With a global presence and dedicated local support teams, we ensure responsive service wherever you operate. Our network enables real-time assistance, and personalized solutions tailored to your region's needs.

Dot Pin Marking Machine

A Dot Pin Marking Machine (also known as a dot peen marker) is a permanent marking device used to engrave or etch information onto various materials, primarily metals and hard plastics.

Key Features:

- Permanent marking

- High-speed engraving

- Suitable for flat, curved, or irregular surfaces

- Marks can include: Serial numbers Barcodes / Data Matrix codes Logos Dates & batch numbers

Portable Dot Pin Marking Machine

Portable dot pin marking machines, also known as dot peen markers, use a stylus to create a series of indented dots that form permanent marks like text, serial numbers, DataMatrix codes, or logos.

CO2 Laser Cutting Machine

High-Precision Cutting for Non-Metal and Thin Metal Materials

Our CO₂ laser cutting machines deliver exceptional precision and speed, ideal for processing non-metallic materials such as acrylic, wood, plastic, leather, textiles, and select thin metals. Designed for high performance and reliability, these systems are perfect for industries requiring clean edges, detailed cuts, and consistent results.

- High-Precision Cutting

- Wide Material Compatibility

- Efficient Exhaust and Filtration System

- Advanced Motion Control System